Standards

In various examples listed on our website, measurements are shown on different surface standards explained below.

Calibration standards

Calibration standards are traceable test specimens:

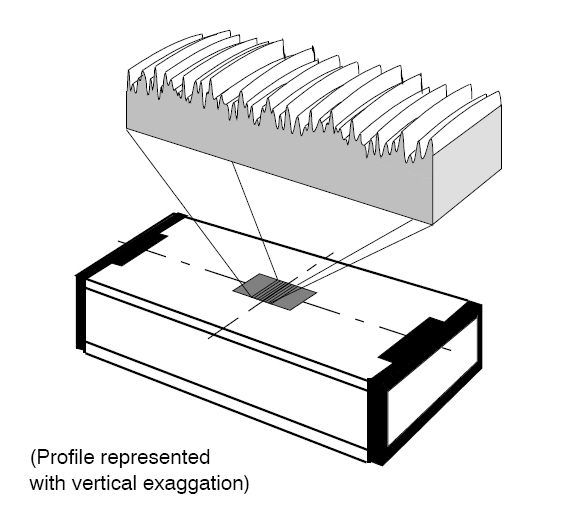

The PTB depth setting standard is used to calibrate and check the vertical magnification of surface measuring instruments (tactile as well as optical) using calibrated groove depths (vertical dimensions) of the test specimen. The groove depths are in the µm range.

The PTB roughness standards are used to calibrate and check the entire surface measuring instrument (tactile as well as optical), since due to the "one-dimensionality" of the roughness not only the local groove profile amplitudes (vertical dimensions) but also the associated local lateral dimensions (horizontal dimensions) are defined.

The PTB roughness standards are available in three roughness classes Ra from 0.25 µm to 1.5 µm (4058/01) or in superfine version in three roughness classes Ra from about 25 nm to 80 nm (4070/03).

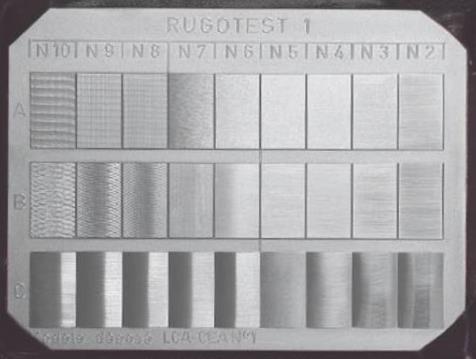

Comparison standards

Comparison standards such as the RUGO standards, on the other hand, are only used for the visual comparison of surface measuring instruments on the basis of typical production-related surface characteristics. The vertical and horizontal dimensions are not exactly defined.

The individual fields of the RUGOTEST 1 correspond to the manufacturing types of roll milling, face milling, planing/turning, grinding, lapping, honing and superfinishing with roughnesses of Ra between 12.5 µm and 0.05 µm.